Our investment in nappy and absorbent hygiene products (AHPs) recycling, in collaboration with the University of Brighton, has led us down some very promising paths. As highlighted in our previous blog post, we’re not the first company to find a recycling solution to one of the biggest waste problems in the world – but we do feel that we’re very close to finding a solution.

One of the major reasons why past AHP recycling projects have failed is because they’ve struggled to find commercial opportunities. In order to justify recycling a product, it has to cost more or the same as incinerating it. In this blog post, we are going to discuss the commercial opportunity of collaborating with paper mills to develop AHP recycling on a grander scale and solve some of the environmental issues that the paper industry is facing.

The current state of affairs for paper recycling in the UK

According to the Environmental Paper Network in 2018, paper consumption is set to increase globally and most of which will be used for packaging and wrapping purposes. The UK consumed about 145 kg of paper-based products per person in a year, which is 2.63 times the global average consumed.

The three core pulp/paper manufacturers in the lead are DS Smith Paper Ltd (14.8%), UPM-Kymmene UK Ltd (10.9%) and Iggesund Paperboard Workington Ltd (8.4%) (IBISWorld 2019).

There will be a continuing demand for good quality pulp which, if unfulfilled, will be replaced with virgin fibres, increasing demand on natural resources.

What are the challenges for reclaimed nappy fibres?

We have discovered that cellulosic fibres from nappies and other AHPs would be a sustainable material used to create paper and enable the industry to act within a more circular economy. However, there are challenges for reclaimed nappy fibres that our team of scientists and researchers are exploring solutions to.

Recovered paper wastes are beset by three main sources of contamination. Firstly, compared to pulp from virgin fibres, recycled fibres potentially increase microbial contamination (Johansson et al. 2001). Secondly, fibres contaminated with food contain oils that are detrimental to fibre quality, such as strength and appearance, because the oils are not easily separated from the fibres during processing (Defra 2012; DS Smith 2017). These two are risks that post-consumer nappies will contain if not adequately pre-processed.

Then there are the challenges within the paper industry itself, which is highly regulated with regard to environmental impact and product standards (IBISWorld 2019). This suggests that paper makers may be reluctant to diversify reclaimed-pulp sources.

What are the opportunities for reclaimed nappy fibres?

Whilst it’s important to highlight the challenges that our team are facing, we should also state that reclaimed nappy fibres have enormous opportunities. For example, cellulose-based pulp in pre-consumer nappies is of high quality, and fibre lengths are typically long as they are produced from softwoods (EDANA 2008 p.41). Depending on the end use, certain other quality requirements must also be met, such as mechanical strength and absorption capacity.

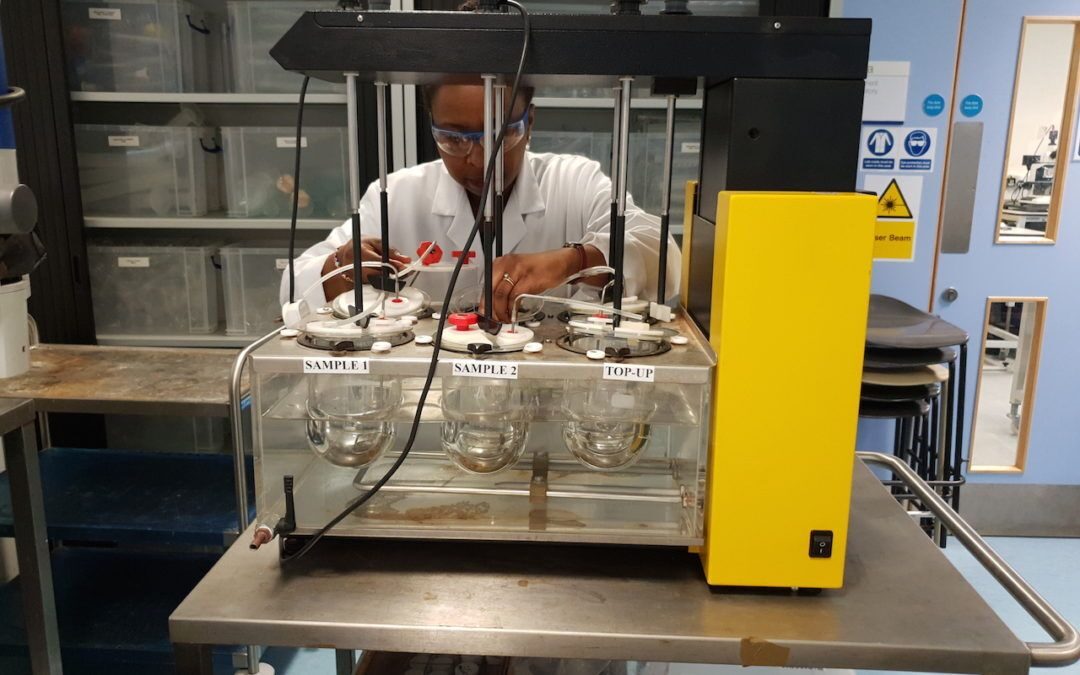

Medisort Ltd is in partnership with the University of Brighton to explore reclaimed nappy fibre quality characteristics, commercially viable nappy waste transformation processes and end markets.

If you would like to get involved in this project, please email webenquiry@medisort.co.uk.

References

Defra (2012). Project WR1210 – How can paper be made more sustainable? [Online]. Available from:

http://randd.defra.gov.uk/Document.aspx?Document=WR1210SustainablePaper-FinalReport-PublishedFeb2012.pdf (accessed 08 June 2019).

DS Smith (2017). Contamination costs where quality counts [Online]. Available from:

https://www.dssmith.com/paper/insights/blogs/2017/7/contamination-costs-where-quality-counts (accessed 07 June 2019).

European Disposables and Nonwovens Association, EDANA (2008). Sustainability Report 2007–2008 Absorbent

Hygiene Products [online]. Available from: https://www.edana.org/docs/default-source/default-document-library/sustainability-report-2007-2008-absorbent-hygiene-products.pdf?sfvrsn=2 (accessed on 5 February 2018).

Environmental Paper Network (2018). The state of the global paper industry. Shifting seas: New challenges

and opportunities for forests, people and the climate. [Online]. Available from: https://environmentalpaper.org/wpcontent/uploads/2018/04/StateOfTheGlobalPaperIndustry2018_FullReport-Final-1.pdf (accessed 11 June 2019).

IBISWorld (2019). IBISWorld Industry Report C17.120 Paper & paperboard manufacturing in the UK. May 2019.

Lawrence Thomas. (accessed 08 June 2019).

Johansson, A., Hallmans, G., Olofsson, C., Gref, R., Svensson, K., Wilhelmsson, A., Lundstro[double dots]m, H.

(2001). Microflora in paper with various contents of recycled fibers. Nordic Pulp & Paper Research Journal. 16(010, 40-45.

Packaging Gateway (2019). Loop: Exploring the impact of TerraCycle’s reusable packaging scheme.

[Online]. Available from: https://www.packaging-gateway.com/features/loop-reusable-packaging/ (accessed 08 June 2019).

Takaya, C.A., Cooper, I., Berg, M., Carpenter, J., Muir, R., Brittle, S., Sarker, D.K. (2019).

Offensive waste valorisation in the UK: Assessment of the potentials for Absorbent Hygiene Product (AHP) recycling. Waste Management. 88, 56-70.